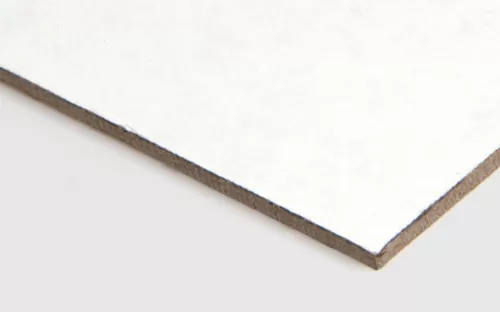

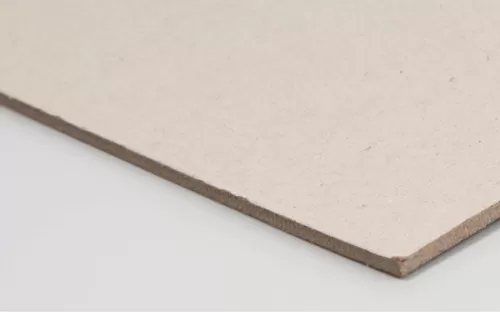

Natural Cardboard provides the perfect surface for an organic look. Made from 80% virgin wood fibre, Natural cardboard is 100% recyclable and biodegradable.

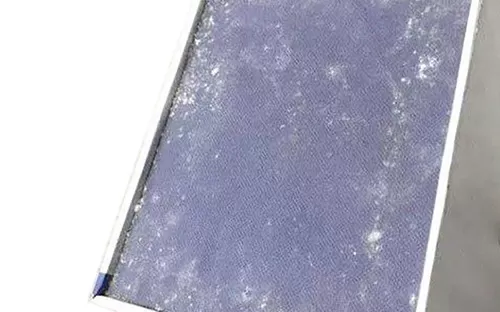

Natural kraft board is made up of 80% virgin pulp fibre, making it up to 100% recyclable and biodegradable. This material is brown in color and offers optimal durability as well as tear and dust resistance, making it ideal for packaging products for shipping. Natural Kraft boards are in fact the industry standard for producing corrugated packaging, making this material readily available and fairly cost effective to produce. However, the brown color of this material may alter printing output to appear more muted or faded. Although, bleached white or Kemi white liner boards tend to be a little more costly, if your brand requires vibrant designs, considering the extra cost may be worth while.

Corrugated Board Performance:

Single Wall

Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

| 125 lbs/sq in | 23 lbs/in | 52 lbs/m sq ft | 20 lbs | 40 in |

| 150 lbs/sq in | 26 lbs/in | 66 lbs/m sq ft | 35 lbs | 50 in |

| 175 lbs/sq in | 29 lbs/in | 75 lbs/m sq ft | 50 lbs | 60 in |

| 200 lbs/sq in | 32 lbs/in | 84 lbs/m sq ft | 65 lbs | 75 in |

| 250 lbs/sq in | 40 lbs/in | 111 lbs/m sq ft | 80 lbs | 85 in |

| 275 lbs/sq in | 44 lbs/in | 138 lbs/m sq ft | 95 lbs | 95 in |

| 350 lbs/sq in | 55 lbs/in | 180 lbs/m sq ft | 120 lbs | 105 in |

Double Wall

Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

| 200 lbs/sq in | 42 lbs/in | 92 lbs/m sq ft | 80 lbs | 85 in |

| 275 lbs/sq in | 48 lbs/in | 110 lbs/m sq ft | 100 lbs | 95 in |

| 350 lbs/sq in | 51 lbs/in | 126 lbs/m sq ft | 120 lbs | 105 in |

| 400 lbs/sq in | 61 lbs/in | 180 lbs/m sq ft | 140 lbs | 110 in |

| 500 lbs/sq in | 71 lbs/in | 222 lbs/m sq ft | 160 lbs | 115 in |

| 600 lbs/sq in | 82 lbs/in | 270 lbs/m sq ft | 180 lbs | 120 in |

Triple Wall

Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

| 700 lbs/sq in | 67 lbs/in | 168 lbs/m sq ft | 240 lbs | 111 in |

| 900 lbs/sq in | 80 lbs/in | 222 lbs/m sq ft | 260 lbs | 115 in |

| 1100 lbs/sq in | 90 lbs/in | 264 lbs/m sq ft | 280 lbs | 120 in |

| 1300 lbs/sq in | 112 lbs/in | 360 lbs/m sq ft | 300 lbs | 125 in |

E-Flute

Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

| 150 lbs/sq in | 26 lbs/in | 66 lbs/m sq ft | 35 lbs | 50 in |

| 200 lbs/sq in | 32 lbs/in | 84 lbs/m sq ft | 65 lbs | 75 in |

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering