Once jewelry boxes and gift boxes are moldy, they are easy to contaminate products and seriously affect the appearance. Mold has the characteristics of rapid spread and reproduction. If the gift box is moldy, it is easy to cause other materials of the product to grow mold, which will cause great losses to the merchants.

According to our combination of paper packaging box material structure processing technology, it is recommended to follow the following packaging box mold removal method to effectively prevent the problem of packaging boxes from getting moldy again.

Reasons for moldy paper packaging boxes

The moldy packaging boxes are mainly caused by glue. For example, white latex, jelly glue, starch glue and other glues contain starch and protein, which are the nutrient sources needed for mold growth. In addition, the humidity of water-based glue is high, which causes the packaging paper boxes to mold.

Let's take a look at how to repair moldy packaging boxes?

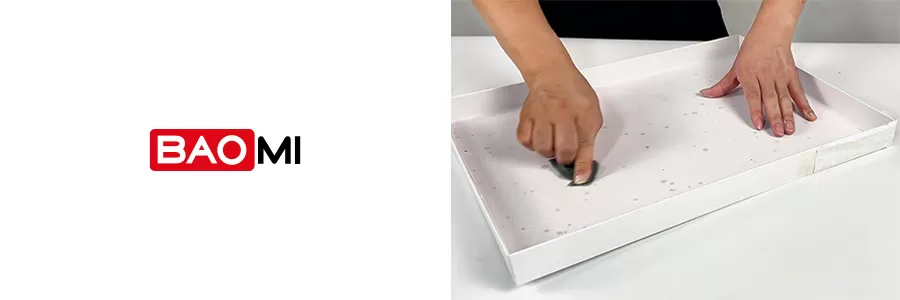

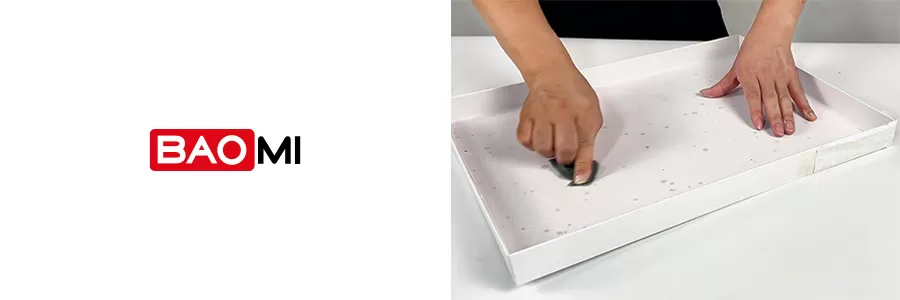

Step 1: Remove mold spots from packaging boxes

Use fine sandpaper to polish the mold spots on the surface of the packaging box to fade the mold spots and make the surface of the packaging box smoother.

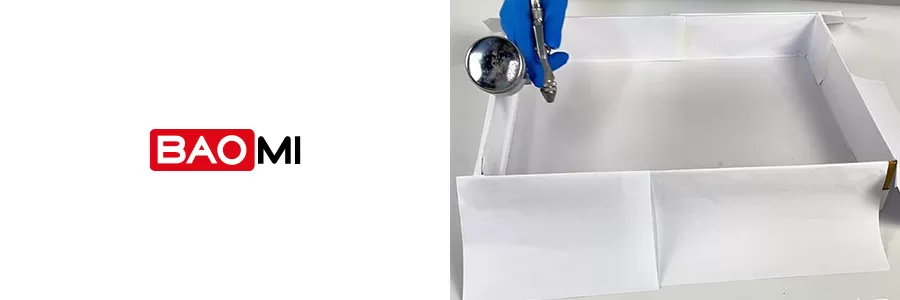

Step 2: Repair the mildew spots on the paper box

Case 1: The packaging paper box only has mildew ash, but no mildew spots:

Use a brush and detergent to clean the mildew areas of the packaging paper box until the mildew ash and fungus corpses are no longer visible to the naked eye.

Case 2: The packaging paper box already has mildew spots:

Use the same color repair agent on the different colored parts around the paper box or the parts that do not need to be repaired, and then adjust the spray gun to the most atomized state, and spray it on the mildew area in small amounts and multiple times to cover the mildew spots completely.

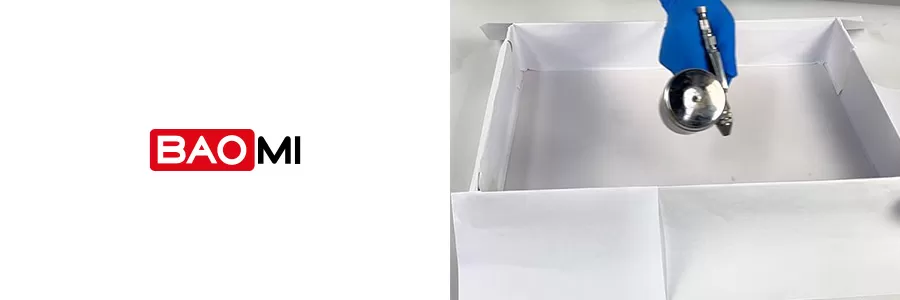

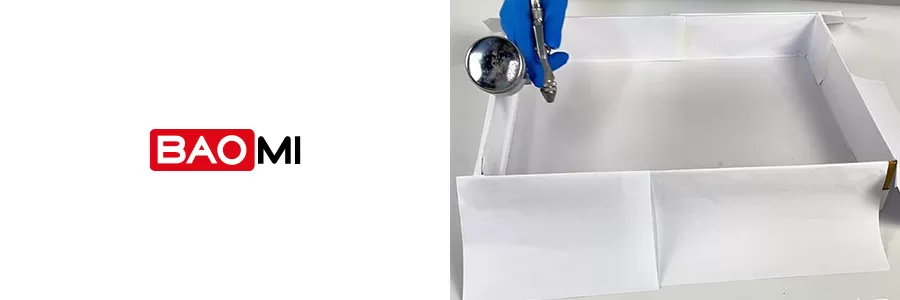

Step 3: Prevent the packaging box from getting moldy

After the packaging box is cleaned of mold spots, wait for it to dry, use a spray gun to load the packaging box with mold inhibitor, adjust the spray gun to a good atomization state, and spray evenly on the inside and outside of the packaging box. After spraying, wait for it to dry before packaging.

Control of warehouse and packaging paper materials reduces the risk of product mold

1. Keep the workshop and warehouse dry and sanitary, keep the items clean and tidy, and reduce the number of colonies in the storage workshop.

2. The selection of materials by the factory is also very critical. Wood, leather, flocking, cloth, paper, etc., must check the humidity of the materials when they are received. When the humidity is greater than 12%, dry it, otherwise there will be a risk of mold (the humidity of the material can be tested with a mildew tester)

3. Finished products and semi-finished products should not be piled directly on the floor. They should be separated by pallets and be >50CM away from the wall. Do not lean materials or materials against the wall. Materials and other materials in contact with the wall will bring the risk of moisture and mold.

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering