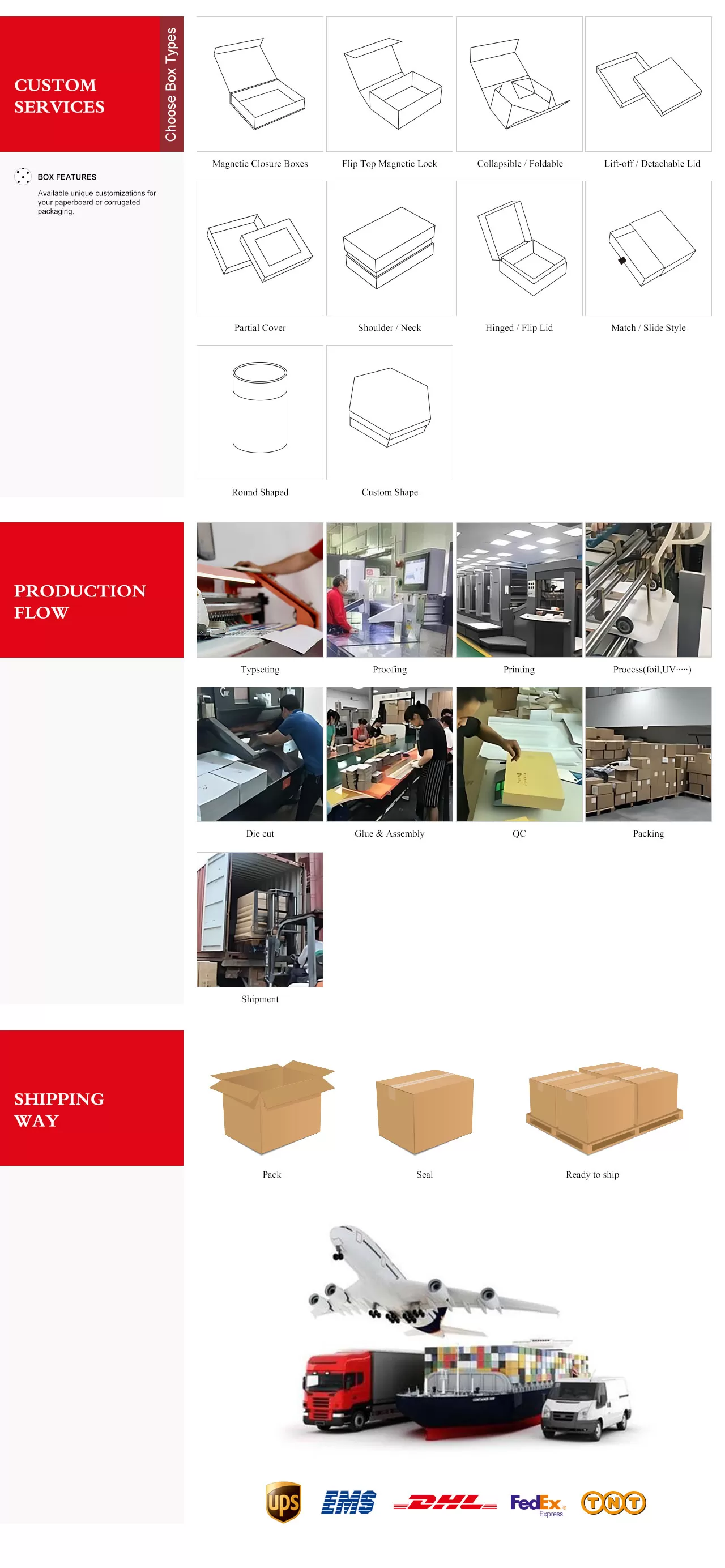

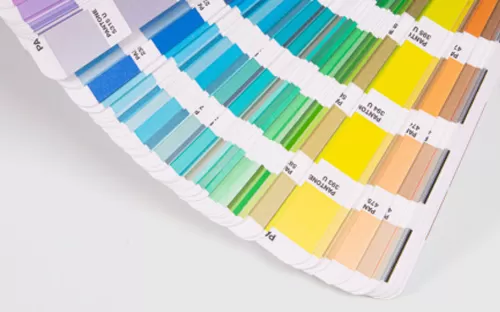

Browse BAOMI ever-growing library of materials, options and packaging features to find how you can make your new custom packaging as impactful as ever.

Browse all options

Shop by Industries

Professional Services

-

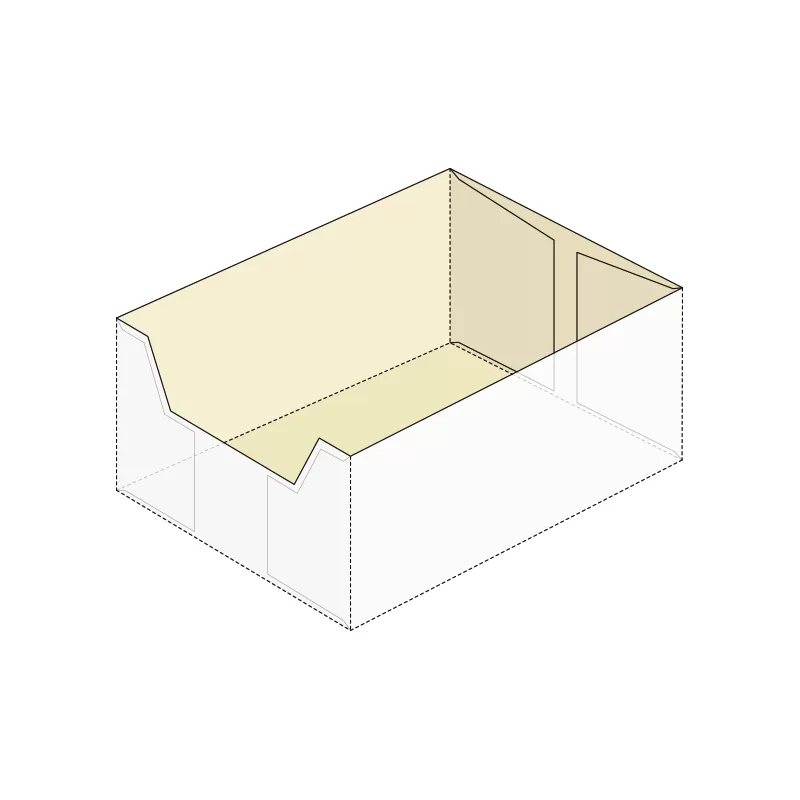

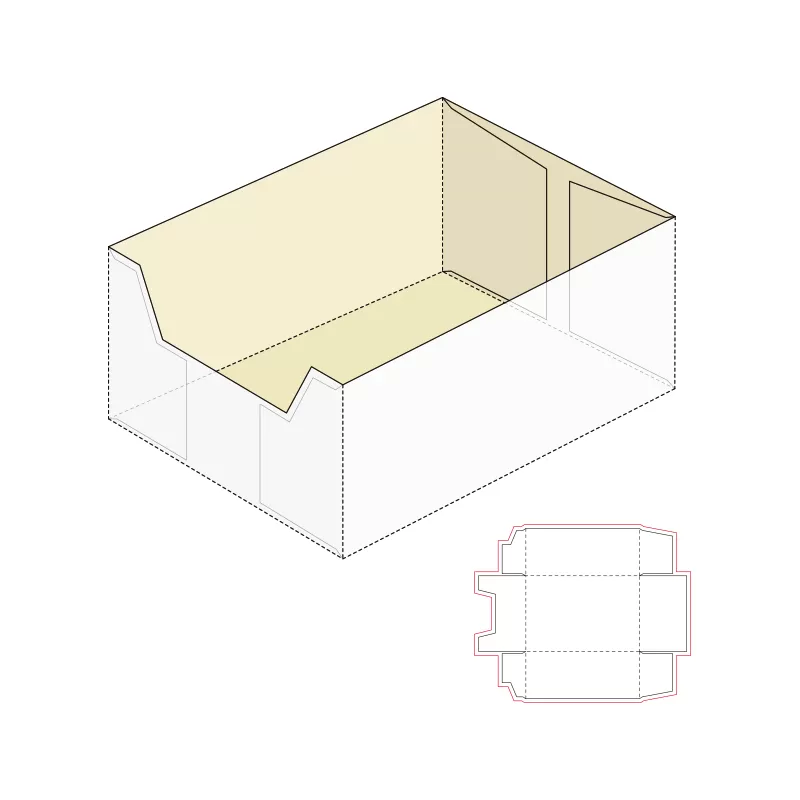

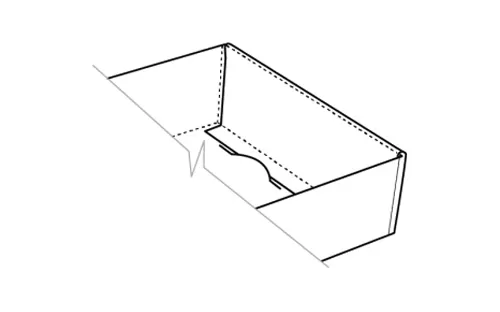

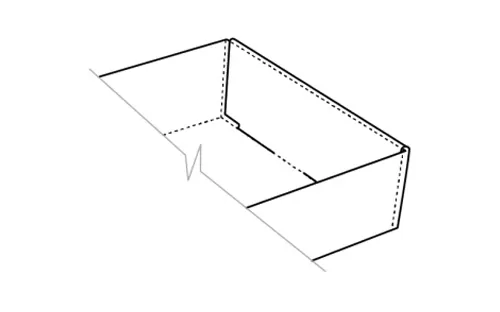

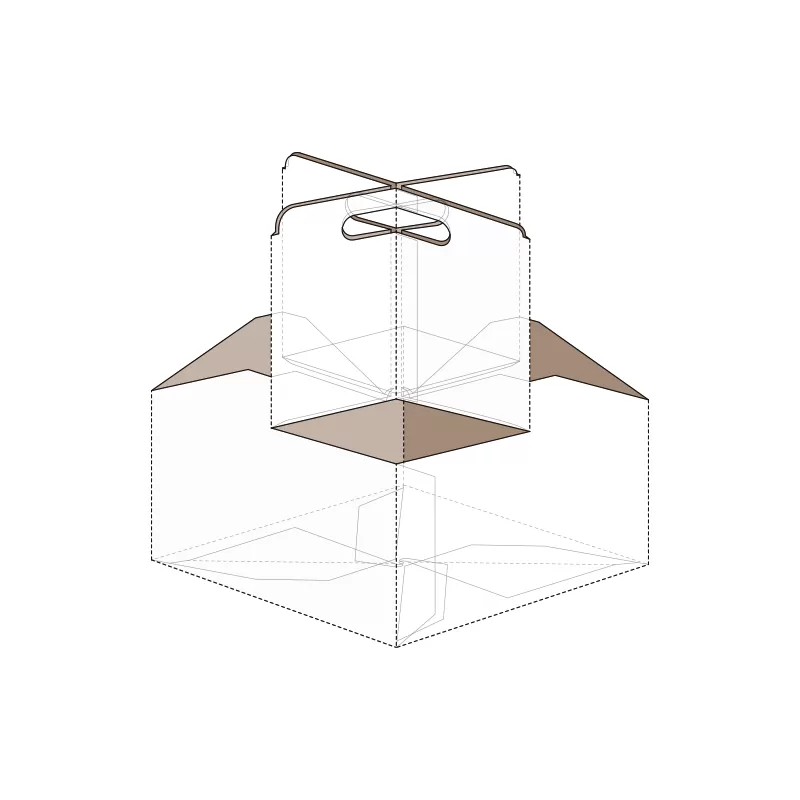

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering -

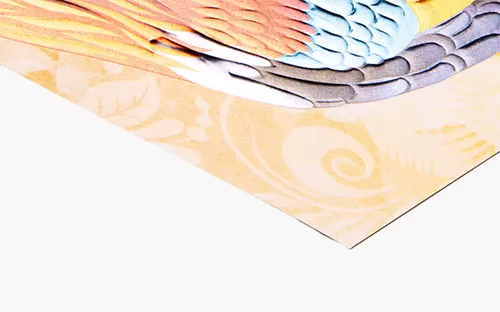

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering -

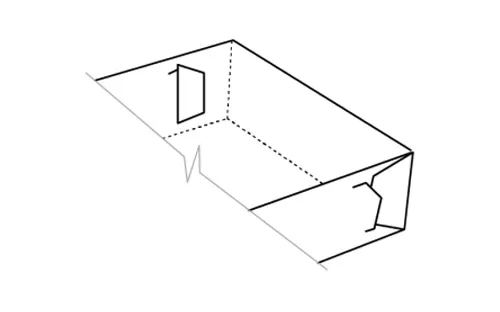

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

What are you looking for?